When the rubber test piece is deformed under the reciprocating cycle force, even if the reciprocating speed is equal,

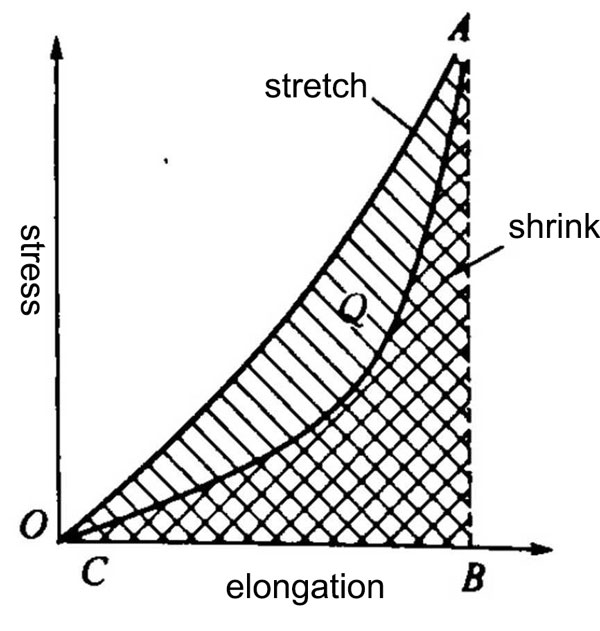

The stress and strain curves do not coincide (as shown in Figure 4-6).

In the figure, OA is a tensile curve and AC is a retraction curve. The area covered by the OAB represents the mechanical work done by the external force on the test piece when it is extended; and the area covered by the CAE represents the work done when the test piece is retracted. The difference between the above two areas (OAB-CAB, that is, the hatched portion) indicates that the mechanical work of the test piece is lost and converted into heat in one reciprocating cycle. If this happens in rubber stoppers or other rubber plugs used under reciprocating forces, it will also heat up and heat up. This phenomenon is called “hysteresis loss”. It can be seen that the rubber will cause heat generation under periodic dynamic stress conditions and affect the service life of the plug (the higher the service temperature, the shorter the service life).

Figure 4.6 Mechanical work done by the rubber being stretched and retracted

When the rubber stopper is subjected to the above-mentioned reciprocating external force, in order to achieve deformation, it is bound to be blocked by the intermolecular resistance, and the strain is delayed from the stress. To achieve excellent dynamic performance, the hysteresis loss should be minimized. However, this degree is affected by the formulation in addition to the frequency of the periodic force. That is to say, under the same dynamic conditions, the hysteresis losses generated are not equal due to the difference in design. Adding a compounding agent (such as a softener or a plasticizer) that helps reduce intramolecular friction or increase intermolecular lubrication can help reduce hysteresis loss.

The above description focuses on measuring “lag loss” from a negative perspective. Indeed, hysteresis losses are detrimental to the use of some rubber products. However, the “lag loss” in some rubber stoppers is precisely the key performance that is deliberately sought.

For example, the damping characteristics of rubber are closely related to the hysteresis loss. The greater the hysteresis loss of a rubber type, the better the damping property and the better the barrier effect on mechanical energy or sound energy. Therefore, rubber stoppers for shockproof, soundproofing, muffling and the like often prefer the butyl rubber with the greatest hysteresis loss in the rubber type. As the use of shock absorbing products becomes more widespread, people will give a more comprehensive and fairer evaluation of “lag loss”.