When the rubber stopper is subjected to an external force (whether tensile or compressive), a certain deformation is inevitable. However, once the external force is removed, the rubber plugs will exhibit an inertial instinct, that is, it will return to its original state in both size and geometry, but it cannot be completely restored to its original state. Residual deformation that can never be recovered. This phenomenon is called “permanent deformation.”

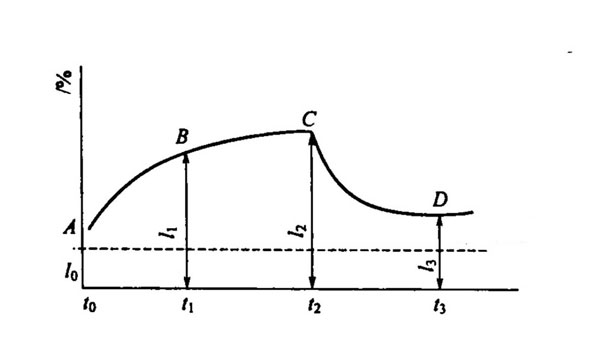

Figure 4-4 shows the physical meaning of permanent deformation.

Figure 4-4 shows that the rubber test piece is continuously stretched from 5, and the external force is removed when it is S. song

Figure 4-4 Deformation of rubber after external force and its recovery process

The line CD indicates the recovery process after the external force is removed. After the D point, the restoration of the test piece will be terminated. After parking for a period of time, there will still be a part that cannot be recovered – permanent deformation. The percentage of the residual deformed portion compared to the original size before the test is the tensile permanent deformation ratio. In the same way, under the condition of compressive force, the test piece will also produce compression permanent deformation, and the compression permanent deformation rate can be calculated according to the same reason.

The driving force behind permanent deformation lies in the strong elastic recovery tendency of rubber macromolecules, and the incompleteness of this restoration comes from fatigue on the one hand, and the accurate positive vulcanization is more important. Because no matter how much sulfur or low sulfur will affect the crosslink density, it will affect the rubber’s resilience.

Permanent deformation mainly involves the stability of the shape and size of the rubber plugs. In the course of product use, these two aspects of instability will affect the rubber plug and other components, affecting the function or service life of the product. For example, if the rate of permanent deformation of the rubber is large enough, the basic function of “fastening” will be lost.

Since the rubber plug is used under tensile conditions, the tensile permanent deformation rate specified in the performance index shall not exceed 70%. For another example, the bridge support is long between the pier and the bridge body, and is used under pressure conditions, and its service life requirement is synchronized with the overhaul period of the bridge. Therefore, there is a high requirement for the compression set of the support, and the compression set rate is set to <20%.

In order to reduce permanent deformation, measures can be taken from both the formulation and the process. As for the main material, high-elastic rubber such as natural rubber should be given priority. From a process point of view, it is also crucial to achieve as much vulcanization as possible.